In the fast-paced semiconductor industry, the role of Outsourced Semiconductor Assembly and Test (OSAT) is crucial. This article explores what OSAT entails, its assembly and testing processes, its benefits, and its significance in meeting the growing demands of semiconductor products. Delve into the applied technologies, the evolving landscape, and the future trends that shape the trajectory of OSAT in the semiconductor ecosystem.

I. What is OSAT?

Outsourced Semiconductor Assembly and Test (OSAT) refers to the outsourcing of the final stages of semiconductor manufacturing, specifically the assembly and testing processes. In this model, semiconductor companies entrust specialized service providers, known as OSAT providers, with the crucial tasks of assembling individual semiconductor components into final packages and conducting rigorous testing to ensure functionality and reliability.

Role of OSAT in the Semiconductor Supply Chain:

OSAT plays a pivotal role in the semiconductor supply chain by taking over the assembly and testing phases. Semiconductor manufacturers, also known as fabless companies, can focus on their core competencies of designing and fabricating semiconductor components, while OSAT providers handle the intricate processes of assembly and testing. This outsourcing strategy enhances efficiency, reduces time-to-market, and allows for a more flexible and cost-effective production model. Ultimately, OSAT contributes significantly to the overall quality and performance of semiconductor products that reach end consumers.

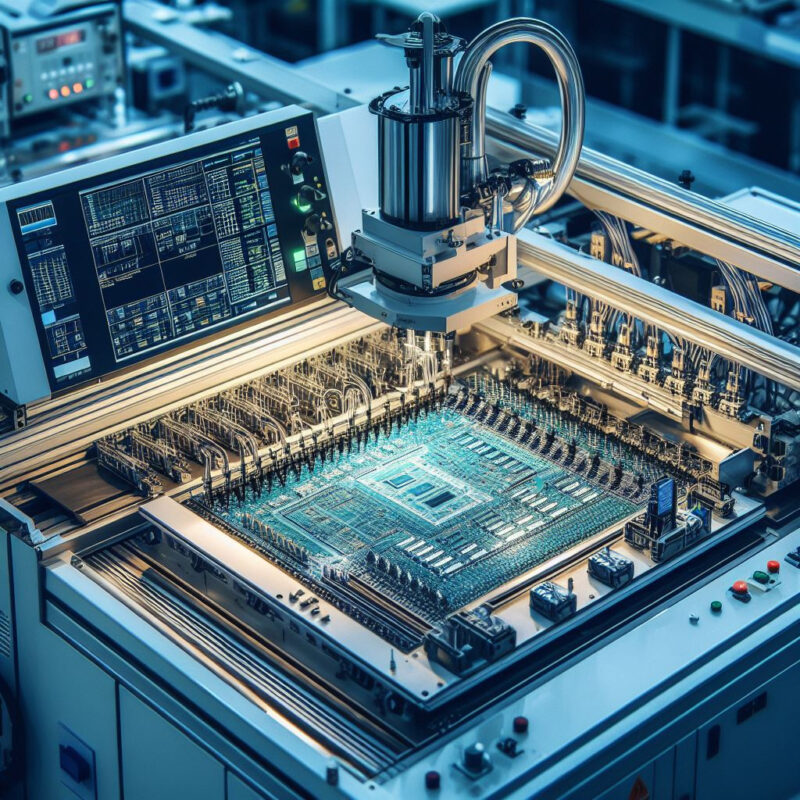

II. Assembly and Testing Process.

The assembly and testing processes are integral components of OSAT, ensuring the final semiconductor products meet stringent quality standards.

- Assembly:

- Component Integration: OSAT begins by integrating individual semiconductor components into a packaged format.

- Surface Mount Technology (SMT): Utilizing advanced SMT, components are mounted directly onto the surface of the substrate, enhancing precision and density.

- Encapsulation: The assembled components are encapsulated to protect against environmental factors and mechanical stress.

- Testing:

- Functional Testing: Rigorous functional tests are conducted to verify that the semiconductor device performs according to specifications.

- Reliability Testing: OSAT subjects the product to various stress tests, assessing its durability and lifespan under real-world conditions.

- Quality Control: Continuous monitoring and quality control measures are implemented throughout the process to identify and rectify any defects.

Significance:

- Quality Assurance: The meticulous assembly and testing stages are critical for ensuring the reliability and functionality of the final semiconductor product.

- Performance Optimization: By identifying and addressing potential issues early in the process, OSAT contributes significantly to enhancing the overall performance and longevity of semiconductor devices.

In essence, the assembly and testing processes conducted by OSAT are key contributors to delivering semiconductor products of exceptional quality and performance to the market.

III. Role in the Industry.

In response to the escalating demand for semiconductor products, the pivotal role of OSAT in the industry becomes increasingly apparent.

- Scalability:

- Meeting Growing Demand: OSAT providers offer scalability to semiconductor manufacturers, enabling them to efficiently scale up production in response to market demands.

- Specialized Expertise:

- Technical Proficiency: OSAT companies possess specialized expertise in assembly and testing, ensuring the seamless integration of semiconductor components and stringent quality control.

- Time-to-Market Efficiency:

- Accelerating Production: By outsourcing assembly and testing, semiconductor companies reduce time-to-market, swiftly delivering innovative products to meet consumer and industry timelines.

- Cost Optimization:

- Economic Advantage: OSAT provides a cost-effective model by eliminating the need for semiconductor manufacturers to invest extensively in assembly and testing infrastructure.

- Flexibility and Innovation:

- Focus on Core Competencies: Semiconductor companies can concentrate on core competencies like design and fabrication, fostering innovation and technological advancements.

- Global Supply Chain Support:

- International Reach: OSAT providers contribute to a globalized semiconductor supply chain, supporting manufacturers in reaching diverse markets with their products.

In essence, OSAT’s crucial role lies in its ability to empower semiconductor manufacturers to meet surging demands efficiently, economically, and with a focus on innovation, thereby sustaining the industry’s growth and competitiveness.

IV. Conclusion.

In summary, OSAT (Outsourced Semiconductor Assembly and Test) stands as a linchpin in the semiconductor industry, playing a vital role in its growth and dynamism. By seamlessly handling the assembly and testing processes, OSAT providers contribute to the industry’s success in several ways:

- Efficiency and Speed:

- OSAT accelerates production, reducing time-to-market and enabling swift responses to changing consumer demands.

- Cost-Effectiveness:

- The outsourcing model of OSAT offers a cost-effective solution, allowing semiconductor manufacturers to optimize resources and allocate capital strategically.

- Quality Assurance:

- Meticulous assembly and rigorous testing by OSAT providers ensure the delivery of high-quality semiconductor products, meeting industry standards.

- Innovation Focus:

- OSAT enables semiconductor companies to concentrate on innovation and core competencies, fostering advancements in technology and product development.

- Global Impact:

- With an international reach, OSAT contributes to the globalization of the semiconductor supply chain, supporting manufacturers in reaching diverse markets.

In essence, the importance of OSAT in the semiconductor industry cannot be overstated. Its multifaceted contributions underscore its role as a key enabler of efficiency, quality, and innovation in the dynamic landscape of semiconductor manufacturing.

Pingback: SMT Unleashed: Innovations in Electronic Manufacturing and Design.